Highlights

Why choose Industrex HPX-Arc 1025 PH?

Advantages of the HPX-ARC

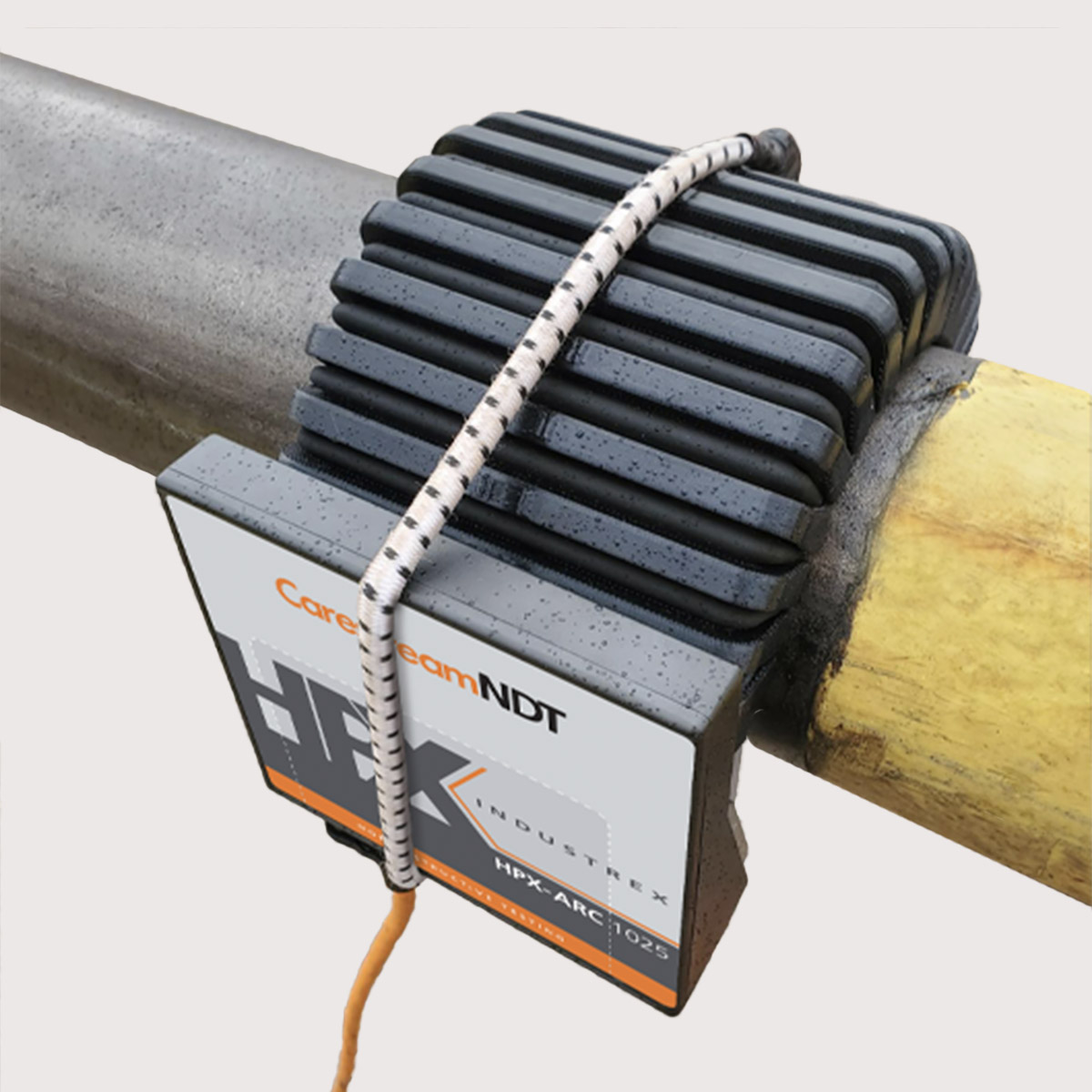

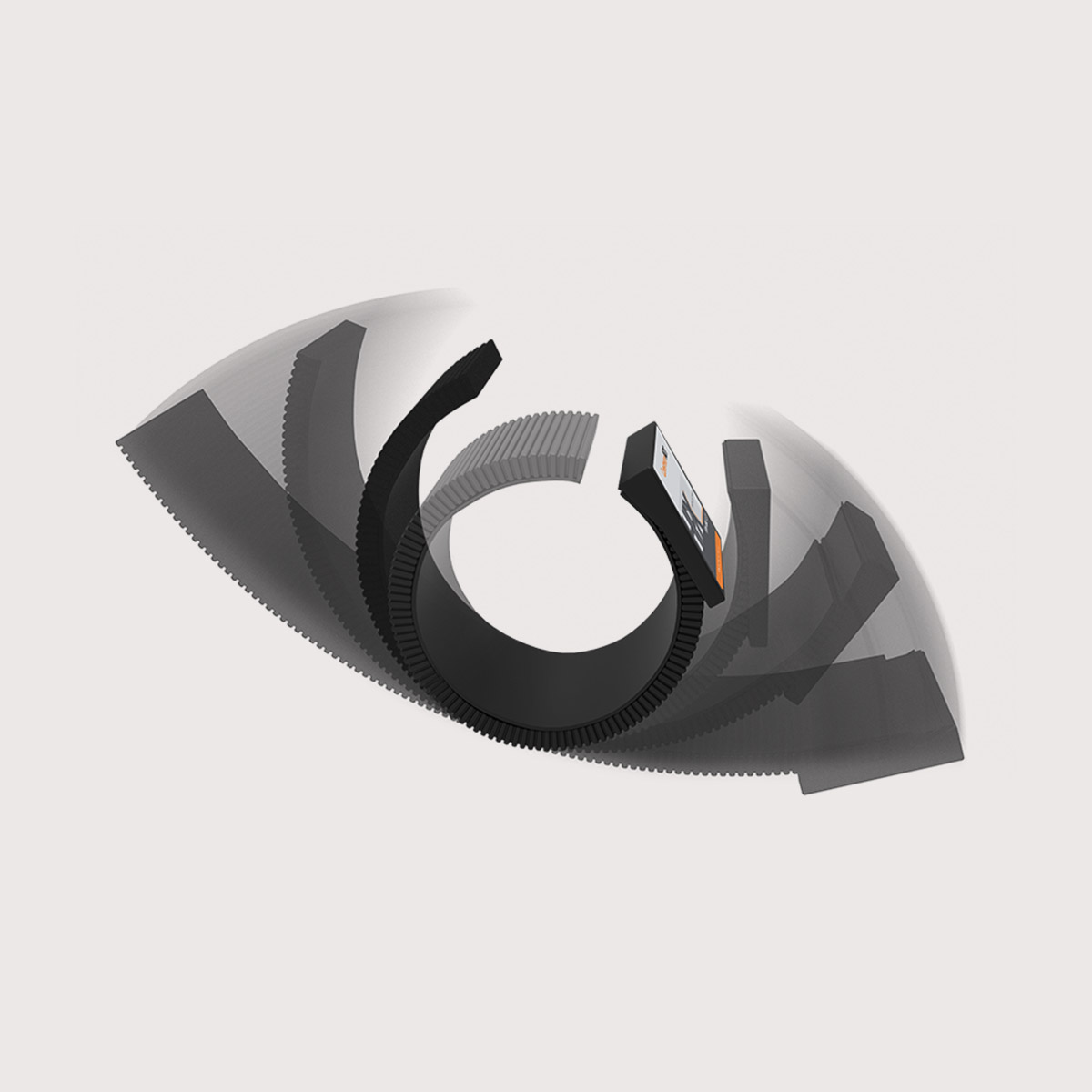

The HPX-ARC offers remarkable flexibility, allowing you to go from a flat position up to a 2-inch diameter to capture detailed images in real time. The absence of films, chemicals and plates simplifies the workflow, providing immediate access to images to optimize operational results.

Superior image quality

With a resolution of 98 μm, HPX-ARC provides high defect recognition capability, ensuring compliance with industry regulatory codes.

Adaptability to different applications and positioning

Available in 10 x 25 cm format, the slim design allows you to capture images on complex surfaces and in tight spaces, increasing versatility in non-destructive inspections.

Instant access to images for quick analysis

Immediate access to images allows technicians to validate IQI sensitivity and radiograph compliance directly at the inspection point. Corrections and new acquisitions can be made on the spot, eliminating the need to return to previous inspection points, as occurs with CR or film methods.

Rugged design for field use

Designed to withstand the harshest conditions, the HPX-ARC is field-tested and features an IP67-rated flexible enclosure that protects against water, liquids and dust.

Greater environmental safety

The use of HPX-ARC reduces radiation exposure, exclusion zone sizes and chemical risks related to film processing, improving operational safety.

Compatibility with different radiation sources

HPX-ARC is compatible with Gamma and X-ray sources, offering a versatile solution for various industrial applications.

Total inspection control

HPX-ARC uses INDUSTREX Digital Viewing software, an integrated platform that allows you to standardize both DR and CR inspections in a single software environment. The software is designed to be intuitive, reducing operator training times and simplifying integration with business processes. Image processing automation features streamline your workflow, improving efficiency and productivity.